Dream Fuel

Synthetic fuel

is now yours

Energy Revolution

from Japan

If you possess some trucks, buses, or airplanes,

never miss this information.

Isn't that wonderful if you could produce

diesel fuel

at 0.15 USD/litter

(0.56 USD/Gallon) by yourself?

Yes, of course, but it is impossible, isn't it?

No, never give up!

Japanese technology has a solution.

Dream Fuel is an energy revolution.

Forget the stereotype that fuel can only be purchased at gas stations.

The time has come when you can purchase Dream Fuel production Equipment and produce your own fuel safely, stably, and inexpensively.

By owning this compact equipment and producing fuel at your own facility, you can produce fuel at less than half the price, or even about 10 to 20% of the market price, without depending on other countries and without being affected by price fluctuations.

It is not a dream. Dream Fuel, successfully commercialized in Japan, has made the impossible possible.

Dream Fuel is a synthetic fuel that can be produced from water, carbon dioxide in the atmosphere, and seed oil, making it surprisingly inexpensive to produce.

Dream Fuel contains no sulfur oxides or nitrogen oxides, making it a wonderful fuel that can be burned to solve air pollution problems.

Moreover, it improves the fuel efficiency of the engine of an automobile by up to 1.2 times, thus increasing the driving distance.

In addition, soot is drastically reduced. Not only is the exhaust gas cleaner, but the engine is also quieter. Knocking is also virtually eliminated.

Dream Fuel such as light oil, kerosene, and n-alkane can be produced.

Please note that gasoline cannot be produced.

You can produce diesel oil stable, safe, and cheap

Less than 0.15 USD/Litter

excluding tax.

Dream Fuel Production Equipment is the solution to save fuel costs dramatically.

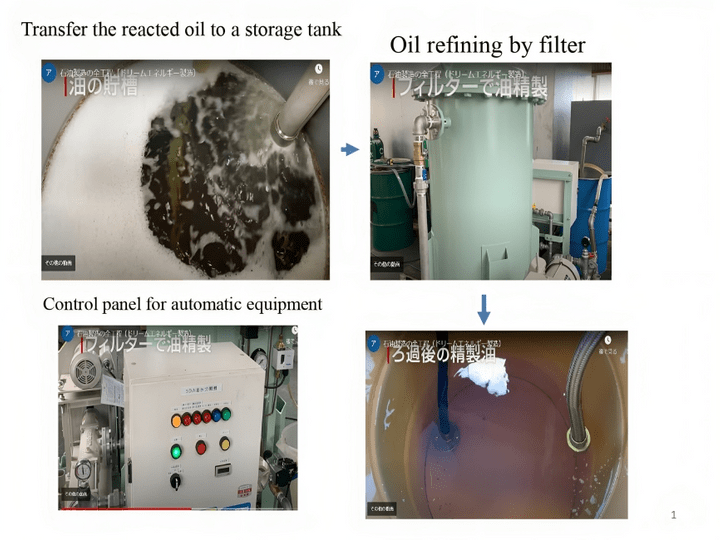

Automatic operation is stable and safe to fuel trucks, buses, airplanes, and boats.

No more dependence on other countries and

oil price fluctuation risk.No more importing oil.

If you possess seven 10-ton trucks, you can save 944,000 USD annually

assuming 400 liters of fuel consumption after the depreciation period.

Dream Fuel does not produce

SOx or NOx.

The Dream Fuel produced by this equipment does not contain sulfur oxide (SOx) or nitrogen oxide (NOx). Zero SOx, NOx

Improved combustion efficiency - increased mileage by 1.2 approx.

Both have the same calorific value.

Dream diesel oil: 46,010J/g

Ordinal diesel oil: 45,990J/g

Results measured according to

the Japanese Industrial Standard

JIS K2279.Carbon Neutrality

Dream Fuel uses Atmospheric CO2 and water to produce fuel.

One of the materials used in Dream Fuel Production is atmospheric carbon dioxide (CO2).

This means that carbon dioxide gas is consumed during the production.Real Carbon Neutrality

Resulting in less environmental impact.

Existing vehicles and equipment can be used without any modification.

Maintain employment in existing vehicle and parts plant manufacturing divisions.

Please give us your opinion and ask for more details on compact equipment.

If you purchase Dream Fuel Production Equipment and calculate the equipment cost over a 7-year depreciation period, you will be able to produce Dream Diesel Fuel for USD 0.36 per liter (excluding taxes).

This is based on the practical assumption that the equipment produces 2,880 liters of fuel daily.

If a normal diesel fuel costs 1.08 USD/L, this means that 0.72 USD/L can be saved. In other words, 2,073 USD can be saved every day. 2,073 USD daily x 20 days x 12 months = 497,664 USD can be saved every year. In other words, you will get back the purchase price of the equipment within about 4 years. However, any taxes are not included.

After the 7-year depreciation period, you can produce Dream Diesel fuel for 0.12 USD per liter (excluding taxes).

If the equipment produces and consumes 2,880 liters of fuel each day, it is estimated that 2,764 USD can be saved each day.

2,764 USD daily x 20 days x 12 months = 663,360 USD can be saved annually after the depreciation period.

Dream Fuel makes the impossible possible.

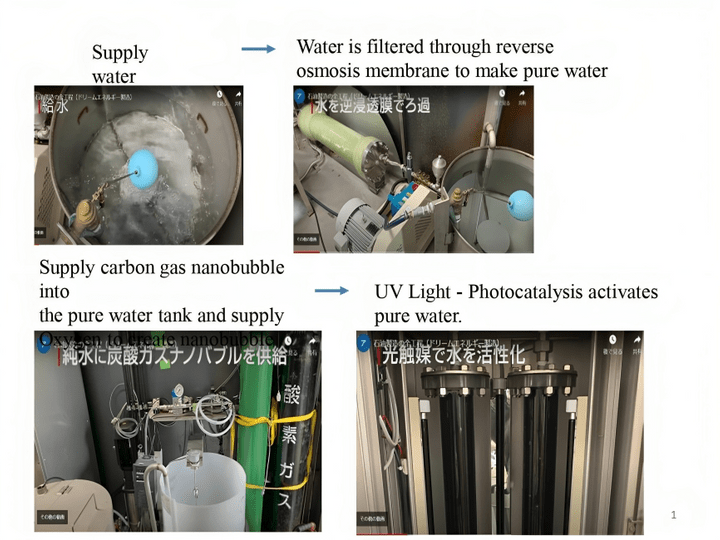

Dream Fuel Production Process

Energy Revolution

We are an official distributor of Dream Fuel Production Equipment in Japan.

This technology will easily solve your country’s emissions and energy problems.

There are four types of production capacity models:

(1) 40 litter/hour type:(960 ℓ/day, 28,800ℓ/month)

(2) 60 litter/hour type:(1,440 ℓ/day, 43,201 ℓ/month)

(3) 120 litter/hour type:(2,880 ℓ/day, 86,400 ℓ/month)

(4) 180 litter/hour type:(4,320 ℓ/day,129,600 ℓ/month)

Dream Fuel can be produced at normal temperatures and pressure.

It does not require huge facilities.This has resulted in inexpensive running costs.

When you hear the words "oil production equipment," you may imagine a huge facility.

This Dream Fuel Production Equipment achieves extremely high productivity by integrating its performance into a single 20-ft container size.

How to make Dream Fuel

STEP 1

Provides carbon dioxide (CO2)nanobubbles (ultrafine bubbles) in water.

Nanobubbles are bubbles on the nanometer order.These bubbles do not rise to the surface of the water but remain in the water.

Hydrocarbons are synthesized by the reduction of carbon dioxide in water.

Supply oxygen to create nanobubble.STEP 2

Pass the water in Step 1 through a special photocatalyst* column and irradiate it with UV light while

circulating the water in the presence of trace amounts of oxygen.

UV light is irradiated while circulating the water.

The oxygen then changes to ozone. Ozone reacts with photocatalyst hydroxyl radicals and other highly reactive oxygen species are generated. These reactive oxygen species reduce carbon dioxide gas to carbon monoxide. 2CO2 ⇒ 2CO + O2 (Reaction 1)

Photocatalyst breaks down water to produce hydrogen and oxygen.2H2O ⇒ 2H2 + O2 (Reaction 2)In reactions 1 and 2,CO2 + H2O ⇒ CO + H2 + O2 (reaction 3)

Carbon monoxide and hydrogen have been generated and are likely to chemically react with each other. The water is activated in a radical state.

The oxygen then changes to ozone.

Ozone reacts with photocatalyst hydroxyl radicals and other highly reactive oxygen species are generated.

These reactive oxygen species reduce carbon dioxide gas to carbon monoxide.

2CO2 ⇒ 2CO + O2 (Reaction 1)Photocatalyst breaks down water to produce hydrogen and oxygen.

2H2O ⇒ 2H2 + O2 (Reaction 2)

In reactions 1 and 2,

CO2 + H2O ⇒ CO + H2 + O2 (reaction 3)Carbon monoxide and hydrogen have been generated and are likely to chemically react with each other. The water is activated in a radical state.

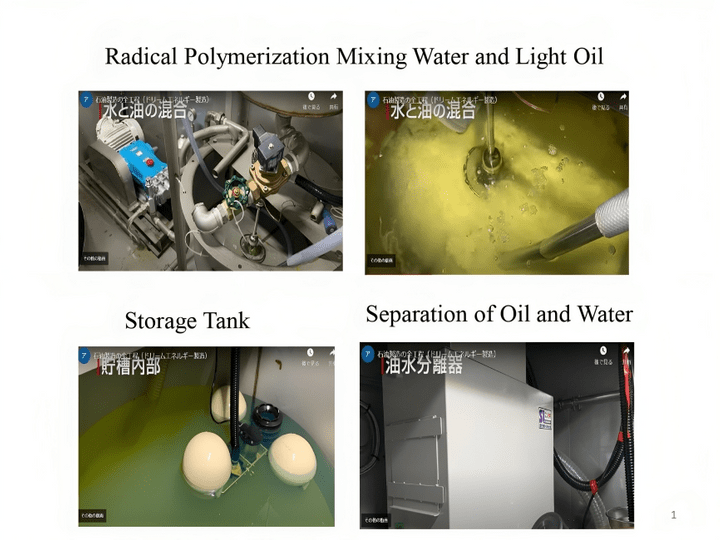

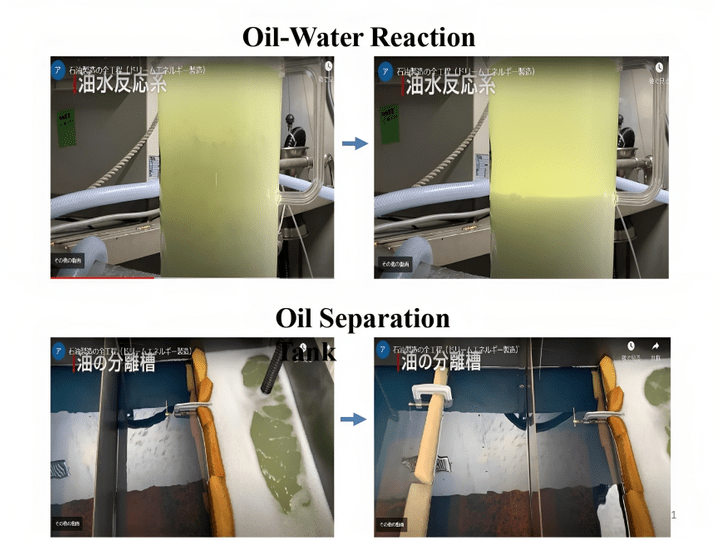

STEP 3

Activated water is mixed with hydrocarbons (seed oil). It will then emulsify and become cloudy

STEP 4

In addition, carbon dioxide gas from the air is absorbed.

Then, carbon monoxide and hydrogen produced in Reaction 3 react in a chain reaction by radical polymerization to produce hydrocarbons (petroleum).

nCO + (2n + 1) H2 ⇒ CnH2n + 2 + nH2O (Reaction 4)

Therefore, nCO2 + (n + 1) H2 ⇒ CnH2n + 2 + nO2 (Reaction 5)

International Patent

Publication number

WO2016/103762

Published Report 1

Chemical Synthesis of Fuel Hydrocarbon from Co2 and Activated Water, and Purification of Commercial Light Oil for Dream Oil

Summary

The greatest thing about this technology is that you can have a fuel production facility at your place even inland, mountainous areas, and countryside with only the size of a 20-foot container area for the smallest one needed to start production as long as you can supply electricity and water. Besides, you can stably, safely, and cheaply produce Dream Fuel.

•Advantages of Dream Fuel production and utilization

1, Reduction of oil import and less dependence on other countries

2, Reduction of the risk of oil import difficulties due to the outbreak of war,

3, Reduction of oil price fluctuation risk

4, Stable and low-cost production of petroleum such as diesel oil, light oil, kerosene, and n-alkane at your own facilities.

5, No SOx, and lower content of NOx and heavy metals compared to crude oil, resulting in less environmental impact.

6, Improved combustion efficiency - increased driving distance

7, Existing vehicles and equipment can be used without any modification.

8, Maintain employment in existing vehicle and parts plant manufacturing divisions.

9, Atmospheric Carbon Dioxide gas is consumed during the production. Carbon neutrality

10, Contributes to the prevention of global warming since CO2 in the air is mainly consumed.

Disadvantage: Gasoline cannot be produced.

Ask for Feasibility Study Documents

We are the official distributor of Dream Fuel Production Equipment

Presented by RadioBio Japan Limited Liability Partnership

Inquiry

info@

© 2019